Modern water treatment consists of a series of chemical and mechanical processes. High-quality, efficient water treatment is critically important to public health and wellness throughout the United States, as well as in most other places throughout the world. As a vital limited resource on which all forms of life on earth depend, water is perhaps the single most precious substance on our planet. Because nearly all people rely on water treatment to ensure the safety and cleanliness of their potable water, water treatment facilities have a public duty to operate at the most effective and efficient level.

Facilities can achieve this through a number of different ways. Water treatment facility solutions can include regular maintenance of existing operations, investing in new operational updates and embracing industry innovations as they are created.

Read the full article or jump to a specific section:

- The Importance Of Improving Water Treatment Facility Operations

- Simple Steps To Improve Water Treatment Plant Efficiency

- Advantages of Installing Shade Structures at Water Treatment Facilities

- Trust USA SHADE With All Of Your Shade Structure Needs

The Importance Of Improving Water Treatment Facility Operations

Like any other mechanical industry, water treatment facilities must continually invest in new technologies and consistent maintenance and evaluation of existing operations to ensure that they are functioning at the highest possible level. Some of the most important factors for facilities to keep in mind include, but are not limited to, the following:

- Public health and potable water access. Recent studies indicate that less than 25% of the earth’s total water reserves are fresh water, and that only 0.04% of this freshwater is fit for human consumption. Humans rely on the work of water treatment facilities to access clean, potable water for drinking, cooking, bathing and brushing teeth, among other needs. It is essential that water treatment facilities commit to concerted efforts to improving their operations and services.

- Energy efficiency. Energy efficiency is highly beneficial to nearly every industry, plant and/or facility — including water treatment facilities and their operations. Investing in eco-friendly, cutting-edge clean energy is a simple way for water treatment facilities to ensure the long-term sustainability of their operations. While implementing clean energy and sustainable energy into operations may be initially expensive, most water treatment facilities will end up cutting costs, increasing efficiency, and, of course, reducing their carbon footprint in the long run. As a result, energy-efficient solutions are an important consideration to keep in mind when improving the operations of a water treatment facility; the opportunities for a significant ROI are quite high.

- Disruptions in service. Regular operations maintenance, improvements and updates are also crucial to a water treatment facility’s ability to provide continuous service. Because water treatment is both a chemical and mechanical process, in which parts of machinery will inevitably break, wear down and/or stop working entirely, regular maintenance should rank high in any facility’s list of priorities. The implementation of operational improvements, as well as the consistent, quality evaluation and maintenance of existing operations, is paramount to both independent water treatment facilities and the water treatment industry as a whole.

- Unexpected repairs and their costs. When a water treatment facility does not perform regular routine maintenance and updates, they will likely experience a reduction in performance and even disruptions in service, as mentioned above. When these types of problems arise, they are nearly always accompanied by expensive, unexpected repairs and service costs. These costs can impact both the owners and employees at the facility, as well as the communities and people which they serve. This is a vital consideration for the owners and managers of water treatment facilities. By investing in regular maintenance and operational improvements, facilities can expect to avoid many of these repairs and the costs associated with them.

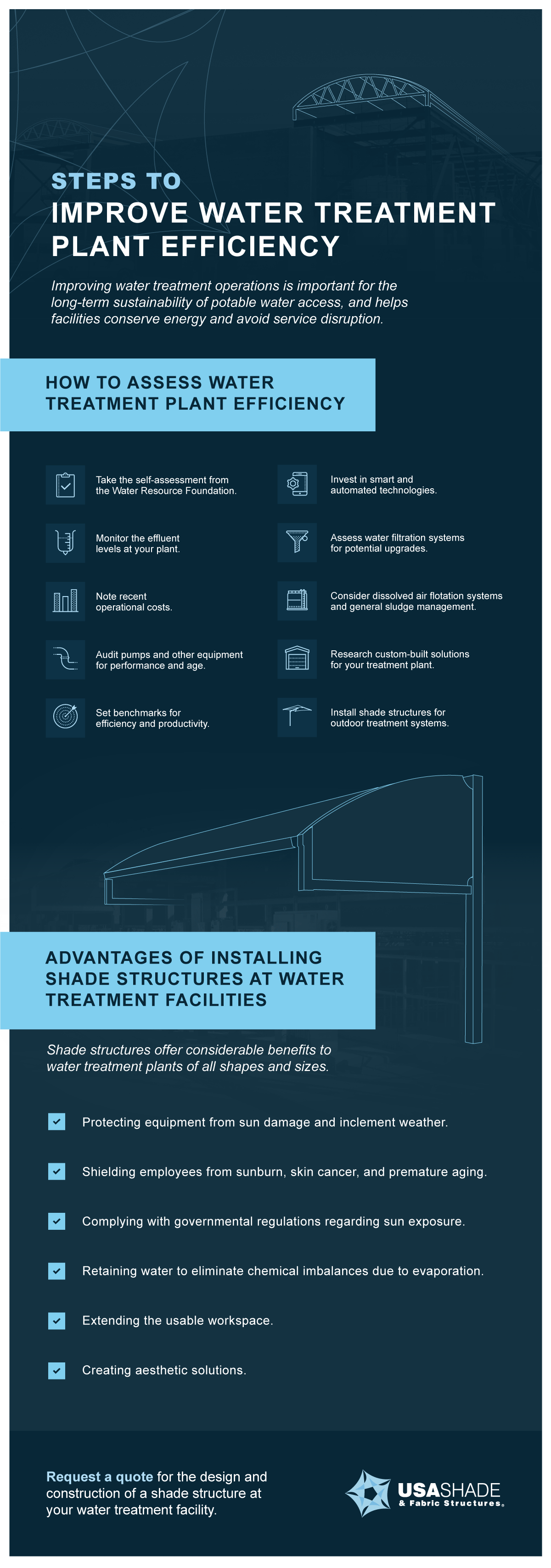

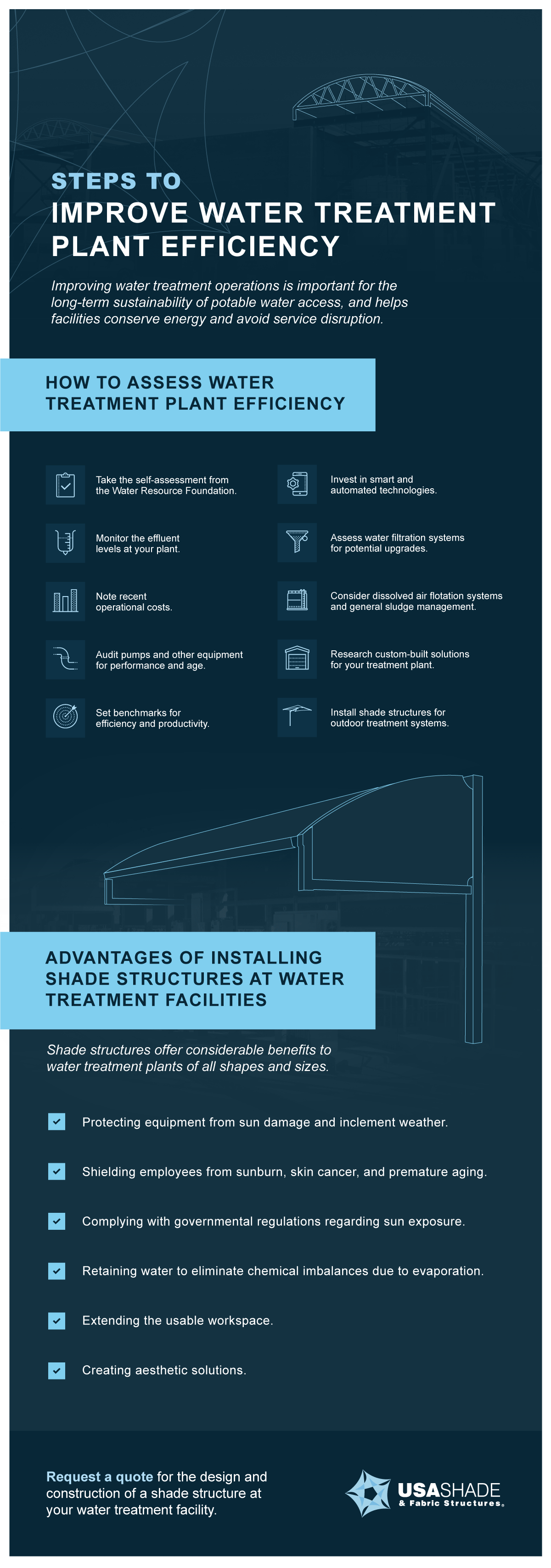

SIMPLE STEPS TO IMPROVE WATER TREATMENT PLANT EFFICIENCY

Improving the productivity and efficiency of a water treatment plant may, from the outset, feel like a daunting and overwhelming venture. While there are certainly many factors and operational aspects to keep in mind, the process of assessing and then improving a water treatment plant can be relatively straightforward. The most important factors, really, are attention to detail, time, research and patience.

Observe current operations with a self-assessment. Many water treatment plants may be unaware of gaps in their service(s), opportunities for operational improvement and/or other productivity interventions, simply because they have not taken the time to closely and methodically observe and then assess current operations. This is one of the most important steps that water treatment facility owners and/or managers must take as part of any plant improvement project. A self-assessment of current operations can include some or all of the following steps:

- Take the self-assessment provided by the Water Resource Foundation (WRF). The WRF provides this self-assessment, formally called the “Performance Benchmarking for Effectively Managed Water Utilities Report.” When used appropriately and accurately, the WRF self-assessment can be a great tool for water treatment facilities. This assessment can provide facility owners and managers with insights regarding their current operational practices, including gaps in performance and other opportunities for improvement.

- Measure the current amount of effluents. An increased amount of effluents can often be one of the most obvious and reliable signs that a water treatment plant is not operating at its highest level of efficiency. The U.S. government — on both federal, state and local levels — as well as governments around the world, often have stringent laws and regulations regarding the effluents and general waste discharge. If you observe an increase in effluents at your plant, it’s generally a sign of a problem that needs to be addressed as soon as possible.

- Take note of recent operational costs. Look over recent costs and expenditures for your plant. If you notice a significant uptick in costs, this can also be a sign that plant operations have been negatively impacted in some way. Aging and out-of-date equipment, as well as frequent disruptions in service (in order to perform repairs), are some of the common causes for sudden increases in a plant’s operational costs. Investing in newer, more innovative equipment and structures is a common way to resolve these types of issues.

- Perform an audit of all pumps and other equipment. Nearly all water treatment plants and facilities rely on some type(s) of pumps in order to perform their treatment(s) effectively. Older-style pumps tend to be much larger than is really necessary by today’s processes and standards. These old, large pumps typically run at a constant speed, and thus may require much more energy and water than newer, updated pumps will require. Water treatment plants can often remedy the problems posed by old pumps by effectively retro-fitting their facilities. Constant speed pumps can be retro-fitted with variable frequency drives (VFDs). With the implementation of VFDs, water treatment plants can expect to see a significant reduction in energy consumption and waste production, as well as an increased longevity for the pumps themselves. Some reports suggest VFDs can reduce energy usage by as much as 50%.

- Evaluate your findings and set a benchmark(s). Once you feel that you have thoroughly and accurately assessed the current operations of your water treatment facility, the next step will be to set benchmarks for your facility moving forward. This will allow for plant owners, managers, operators and other personnel to have a solid understanding of expectations regarding the plant’s productivity and effectiveness. Then, plant employees at every level of the facility’s operations will be better equipped to notice, assess and address any issues with productivity and efficiency moving forward. Water treatment plant owners and managers can look to industry best practices in order to establish benchmarks that are both realistic and helpful.

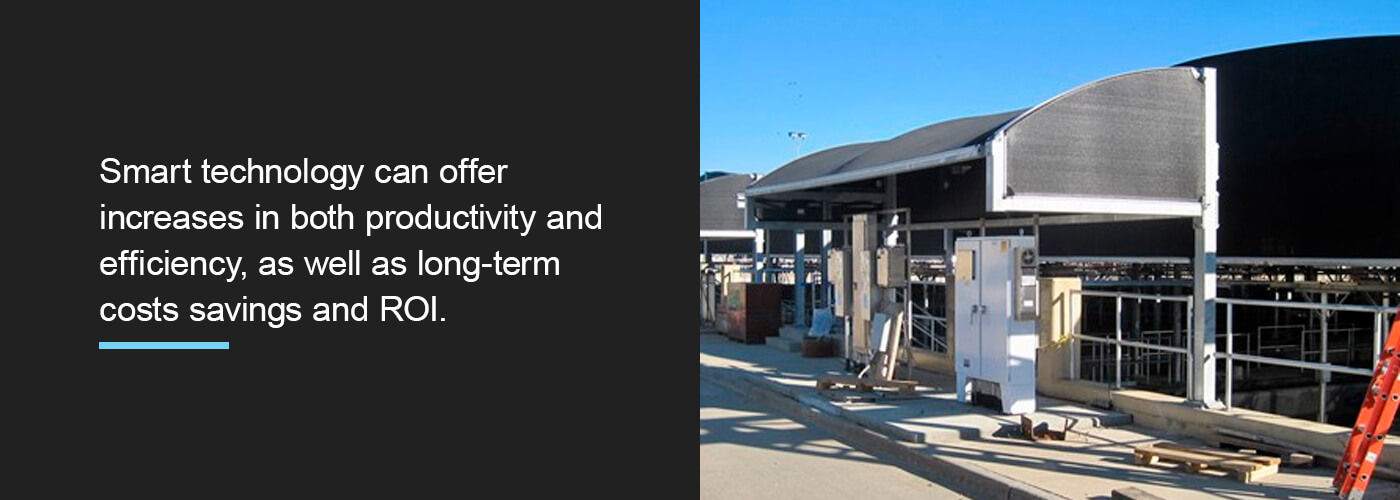

- Invest in smart technology. Technological investments can be some of the most significant and meaningful changes that any water treatment facility can employ. With the recent rise of smart technology, there are more tools than ever before to assist in the water treatment process. Smart technology can offer increases in both productivity and efficiency, as well as long-term costs savings and ROI.

- Water filtration systems. One of the first technological systems that a water treatment facility should assess is its filtration system (and processes). In recent years, there have been significant innovations in common filtration practices, which reduce the amount of backwash created and thus increase overall efficiency. Most filtration systems that have been operational for more than ten years were not created with this new backwash technology in place. As such, water treatment plants should assess the viability of their filtration systems and feel confident to make any necessary upgrades. While filtration upgrades can be expensive, the potential ROI can be quite high. For example, a water treatment plant in Georgia completed a total retrofit of its filtration system in 2013 — the project cost about $12 million USD in total. However, the benefits were extraordinary. Backwash decreased from 200,000 gallons per filter cell to about 90,000 per filter cell. This resulted in an overall increase in energy efficiency and waste reduction for the entire plant.

- Dissolved Air Flotation systems and general sludge management. Similar assessments and upgrades should also be implemented in regards to Dissolved Air Flotation (DAF) systems, as well as flocculation, sedimentation or clarification basins. Like water filtration, each of these waste/sludge management processes can have a marked impact on both the efficiency and the efficacy of the entire plant. Installing high-density sludge processes is a relatively simple way to reduce water wastes, as well as the costs associated with sludge disposal.

- Water filtration systems. One of the first technological systems that a water treatment facility should assess is its filtration system (and processes). In recent years, there have been significant innovations in common filtration practices, which reduce the amount of backwash created and thus increase overall efficiency. Most filtration systems that have been operational for more than ten years were not created with this new backwash technology in place. As such, water treatment plants should assess the viability of their filtration systems and feel confident to make any necessary upgrades. While filtration upgrades can be expensive, the potential ROI can be quite high. For example, a water treatment plant in Georgia completed a total retrofit of its filtration system in 2013 — the project cost about $12 million USD in total. However, the benefits were extraordinary. Backwash decreased from 200,000 gallons per filter cell to about 90,000 per filter cell. This resulted in an overall increase in energy efficiency and waste reduction for the entire plant.

- Automation solutions. Smart technology can also include automation services, such as Automated Meter Reading (AMR) solutions and Advanced Metering Infrastructure (AMI). Both AMR and AMI technologies can greatly impact the day-to-day running of most water treatment plants by eliminating tedious manual information gathering and by optimizing a plant’s entire infrastructure. AMR streamlines the collection of some of the most important plant metrics — such as consumption, diagnostic and operational status information. AMI technology is an even more comprehensive solution than AMR, offering information and status updates in real-time, AMR can also allow for direct communication between service providers and customers. Both of these technologies offer dynamic opportunities for water treatment plants to streamline, simplify and optimize their systems and operations. According to an industry leader, smart technology is on track to become industry standard within the next ten to fifteen years. Water treatment professionals will do well to embrace and implement these technologies sooner rather than later if they wish to remain profitable into the future.

- Research other efficiency and productivity innovations. In addition to pump upgrades and the implementation of new technologies and smart tech automation systems, water treatment facilities can also benefit more out-of-the-box and/or custom-built solutions in order to address specific needs and functions on a plant-by-plant basis. This can include more innovative solutions such as shade structures. Each water treatment plant will have its own unique problems and considerations, so plant owners and managers should keep this in mind throughout their assessment(s), as well as when searching for dynamic solutions. There are always new programs and technological systems entering the market, so frequent research can be key to staying abreast of new developments as they occur.

- Review the data! Most water treatment facilities were originally designed, built and made operational long before real-time metrics and data acquisition were daily concerns. As such, most plant owners and managers may find that the collection and assessment of data does not come naturally to the day-to-day workings of their treatment facility. However, data collection and assessment is crucial. In nearly every case, data is the most efficient and accurate way to monitor plant productivity, efficiency and overall performance. It’s of vital importance that the water treatment industry implement, and make use of, the most accurate data management systems to which it has access.

Don’t overlook the contributions of plant employees, especially technicians, service repair professionals, auditors and bookkeepers, among others. Many employees can offer additional insight and suggestions throughout the plant’s improvement process. It’s important for plant owners and/or managers not to overlook the contributions and facility solutions that employees may be able to offer.

Advantages of Installing Shade Structures at Water Treatment Facilities

Shade structures can offer considerable benefits to water treatment facilities of all shapes and sizes. Shade structures can be custom-built and designed in order to address and accommodate the specific needs of each plant. Though often overlooked, these shade structures can greatly affect the operational functions of water treatment plants, including, but not limited to, the following advantages:

- Protecting equipment. Perhaps the most obvious benefit of installing a shade structure over a water treatment facility will be its capacity to protect equipment such as outdoor tanks, treatment rooms, pumps, filtration systems and other storage facilities. This protection can be especially valuable in locales with inclement weather, like icy, snowy winters and/or extreme heat in the summer. However, the equipment protection afforded by a shade structure is not limited to plants in extreme climates. These structures can also protect equipment from basic sun damage, which can occur virtually anywhere on earth that a water treatment plant is located.

- Maintaining the health and safety of employees. In addition to protecting equipment, shade structures can provide an even more valuable function — the protection of employees. Water treatment employees often face hours of work under the sun, which can pose significant health problems, from sunburns to premature aging to skin cancer. Plant owners and managers have a duty to protect their employees in each and every way possible. Shade structures are a relatively simple, easy way to safeguard employee health, as well as their comfort. With a shade structure in place, it’s much easier to complete general work, maintenance and repairs in all kinds of inclement weather, including heat, rain, snow, hail and more.

- Complying with governmental regulations. Often, some protection against sun exposure is mandated by federal, state and/or local laws. These regulations may be monitored by the local health department, or the Occupational Safety and Health Administration (OSHA). Consequently, if a plant fails to provide these protections to its employees, it may face considerable legal and/or monetary penalties due to OSHA and/or health department non-compliance. As such, it is of great benefit to both the plant and employees’ health and safety to install shade structure(s) throughout all workable areas of the plant.

- Water retention. To give you a sense of how truly hot equipment can get under the sun, consider this recent study conducted by the American Meteorological Society. In the study, researchers found that cars stored under a shade structure were, on average, twenty degrees cooler than cars left out in the open. That’s a considerable difference. Keeping that study in mind, then, it may come as no surprise that baking in the sun all day can actually result in water condensation and evaporation. Water evaporation can have an incredibly negative impact on the efficacy of water treatment plants and their processes. As water in the tank evaporates, it can cause an imbalance in the ratio of water to treatment chemicals. This imbalance affects the quality and efficiency of the water treatment process, and can result in disruption of service, not to mention energy waste and chemical waste. Simply by installing a shade structure, most water treatment plants will be able to eliminate the problem of evaporation almost entirely.

- Extending the usable area. Shade structures can also provide for additional workable space, simply by extending the usable area. This additional workable space can be used in a wide variety of different ways — such as on-site office space for personnel, storage, flex space and other functions. By extending the usable area, shade structures can allow water treatment facilities to grow and expand along with their business, with minimal disruption to service and relatively low construction costs.

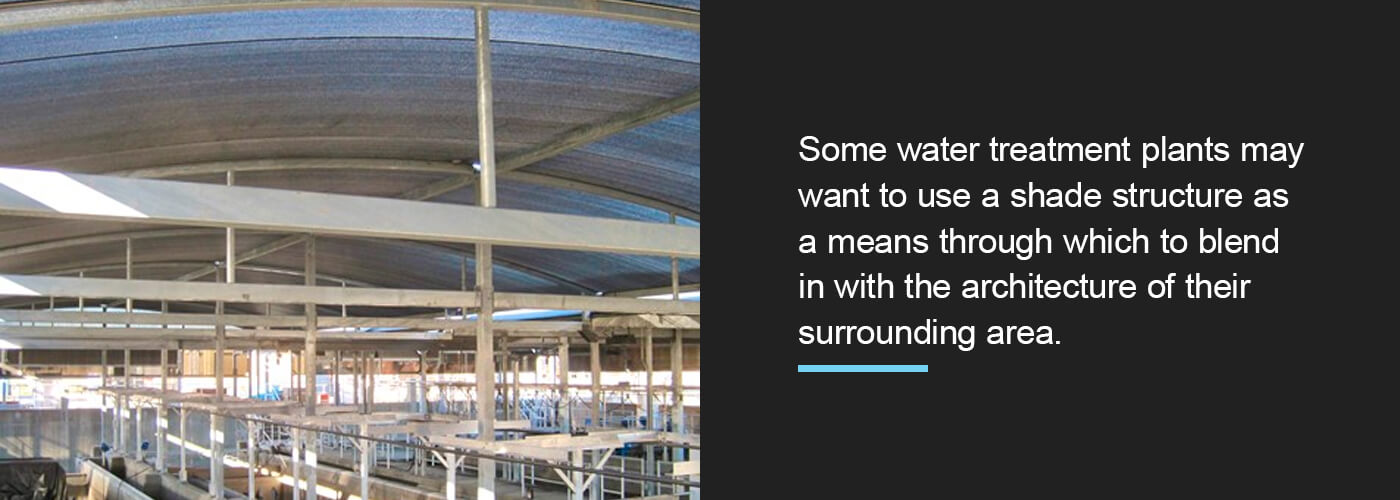

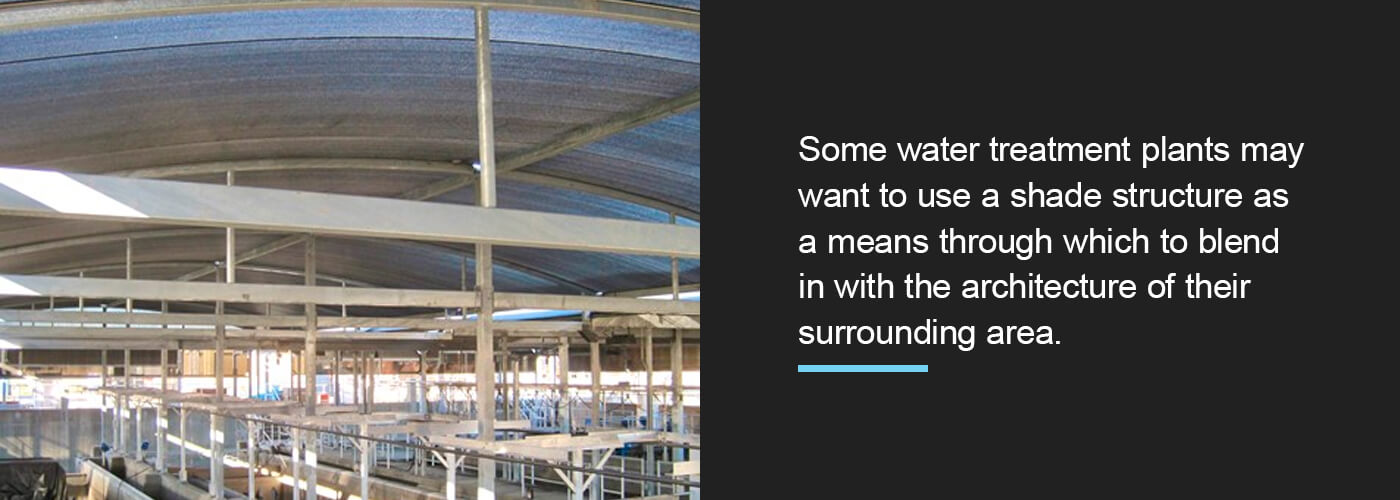

- Creating aesthetic solutions. Though critically important to the communities that they serve, water treatment plants are not known for being visually appealing. Some water treatment plants may want to use a shade structure as a means through which to blend in with the architecture of their surrounding area. Expert, comprehensive providers, such as USA SHADE, can design and construct custom shade structures for your water treatment plant that ensure both functionality and a visually attractive design. USA SHADE employs a skilled team of experienced designers, all of whom are well-versed in the use of many different materials and aesthetic styles.

Trust USA SHADE With All Of Your Shade Structure Needs

With years of experience and proven expertise, USA SHADE is an industry leader in the design and construction of shade structures. We pride ourselves on delivering the highest quality solutions for our clients throughout the country. Our shade structure solutions can be custom-designed to accommodate a variety of specific needs and features. In addition, we are available to support our clients throughout every step of the design and construction process. Our customer service is world-class, meaning that client satisfaction and certified quality work are always our primary objectives.

Do you have questions about shade structures and their benefits? At USA SHADE, we are confident that we can provide you with the best possible solution(s). Contact us today and we will be happy to guide you through every aspect of shade structures — from planning to design to construction and maintenance. We will be happy to assist you in in every way that we can.

If you’re ready to create a state-of-the-art shade structure for your facility, request a quote and we will connect you with our design team.