Some water treatment plants use fragrances to mask odors emanating from the wastewater. In these cases, designers may want to include a small piping system to transport the fragrances.

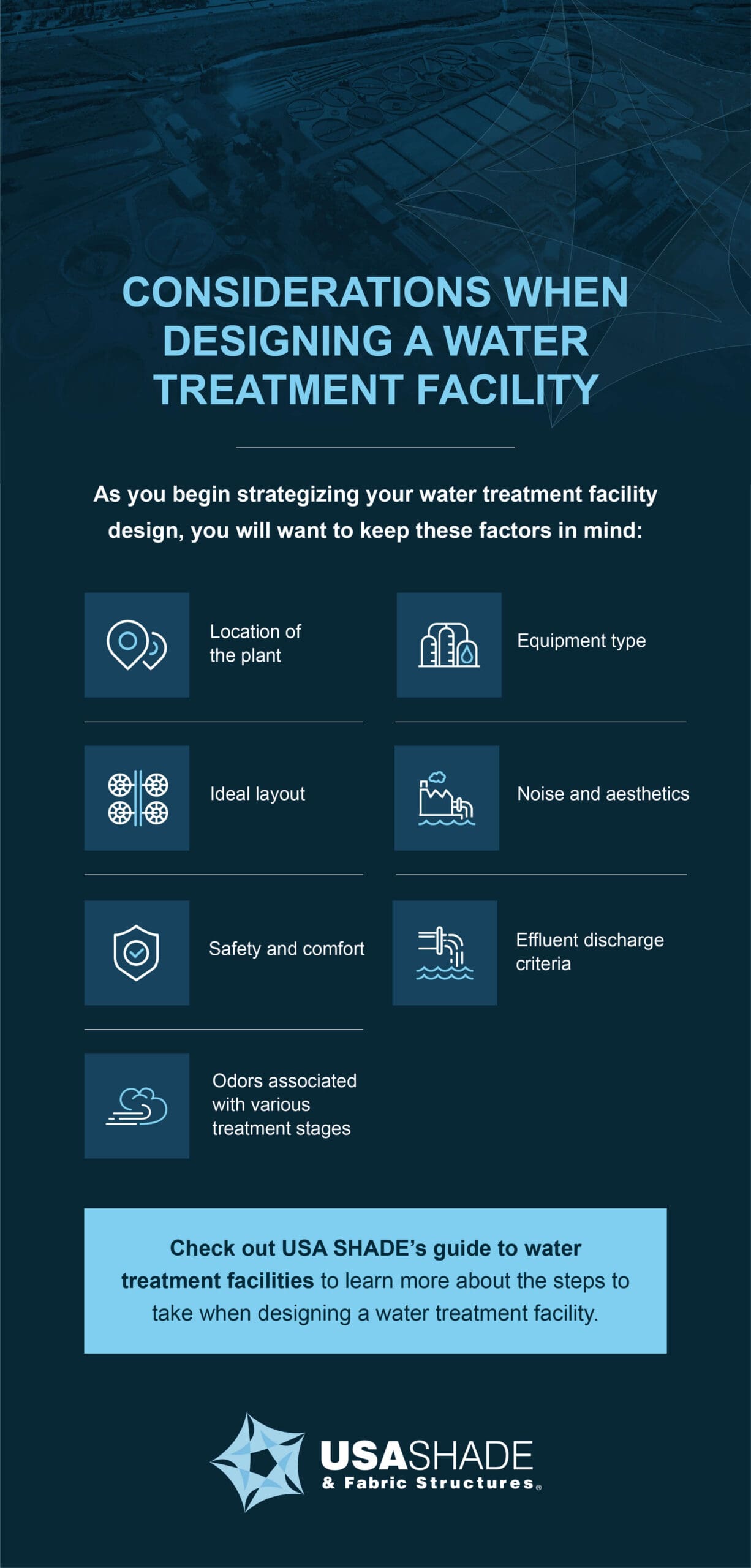

5. Equipment Type

Ideally, the design of a new water treatment plant accommodates all processes necessary for treatment, and those processes are optimized for the facility’s layout. For example, if certain constraints require the facility to be relatively compact, the plant may choose to use membrane bioreactors (MBRs) because of their smaller footprints.

Some plants use biological scrubbers for odor control to minimize the addition of chemicals to the water. Further, adding biological scrubbers to a plant’s layout can help minimize its visual impact on the surrounding environment. Biological scrubbers are generally not as tall as chemical scrubbers, so they stick out less in the landscape. These are also relatively easy to design in a way that keeps the area looking nice for residents while still allowing the plant to do its job.

However, despite the advantages of biological scrubbers, some plants prefer chemical scrubbers because they have used them for years and know they work reliably. Chemical scrubbers generally use nozzles to spray oxidants such as sodium hypochlorite and sodium hydroxide into the air rising from the wastewater. The chemicals bind to and oxidize odor-causing compounds in the air, generating harmless byproducts.

Because chemical scrubbers are relatively tall, the design team may look to features they can add to camouflage or hide these structures. For example, architects and designers might decide to add an attractively designed wall in front of the scrubbers. They may also contract to have a mural or other artwork added to the wall to boost aesthetic appeal.

6. Noise and Aesthetics

The type of equipment chosen for the plant often has an impact on the noise pollution generated. In some cases, design teams have little say in the equipment the plant uses. If they do, however, they can choose equipment with low decibel ratings to eliminate nuisance noise. For example, high-speed turbo blowers are often much quieter than equipment such as multi-stage centrifugal blowers or positive displacement blowers.

Even if the design team has no say in the equipment, it can develop a design that optimizes noise containment. Acoustic treatment to the walls housing the equipment can do a lot to help a plant quietly coexist with the surrounding community. Some types of equipment also come with acoustically insulated enclosures that the design team can use to muffle sounds.

A design project will likely also want to ensure the facility blends in with the landscape as much as possible to avoid provoking complaints from residents about its appearance.

7. Effluent Discharge Criteria

One of the most important steps the design team can take is to establish the guidelines the facility’s discharged effluent must meet. They can then ensure the facility contains the correct equipment and layout to meet those criteria and comply with the law.